Equipped with the machinery required to fabricate and move large, heavy parts, Industrial Pattern & Mfg. was approached by a customer in the truck manufacturing industry to produce a permanent mold assembly used for casting the aluminum suspension brackets found in class 8 vehicles (16.5+ ton trucks and tractor trailers).

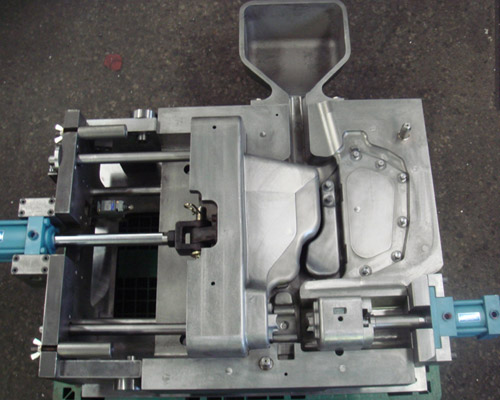

Working from customer supplied prints, we utilized horizontal and vertical machining centers to mill components for this mold assembly from class 40 cast iron. We fabricated additional components from H-13 steel, chosen for its high resistance to thermal fatigue cracking which can occur as a result of the cyclic heating and cooling cycles of the casting process. All parts were hand finished to ensure they were entirely free of defects. Secondary operations consisted of assembling the 6,000 lb., 48” x 42” x 24” permanent mold before shipment to the customer.

At Industrial Pattern & Mfg., our advanced technology equipment and skilled craftsmen are dedicated to delivering permanent mold assemblies that enable long-term fabrication of tight tolerance parts. To learn more about this project or how our permanent mold assemblies can enhance your casting operations, contact us today.

Permanent Mold Assembly Project Highlights

| Product Name | Permanent Mold Assembly |

| Product Description | This permanent mold is used to make aluminum suspension brackets for class 8 vehicles. |

| Capabilities Applied/Processes | Primary: Vertical CNC Machining Horizontal CNC Machining Secondary: Mold Assembly Turning |

| Overall Part Dimensions | Length: 48" Width: 42" Height: 24" |

| Weight | 6,000 lbs. |

| Material Used | Class 40 Iron H-13 Steel |

| Material Finish | Hand Finished |

| Mold Type | Semi Permanent |

| Industry for Use | Truck |

| Delivery/Turnaround Time | 14 - 16 weeks |

| Delivery Location | USA Mexico |

| Standards Met | Customer supplied data |